offers

Liaison Stainless specializes in a number of carbon, alloy & stainless steel grades. The following are some of our current competitive product offers, catering but not limited to the following industries:

- Auto components

- Dairy machinery

- Ball and Roller Bearings

- Pumps (including submersible and water bearing pumps)

- Oil Refining

- Textile Machinery

- Printing Machinery

- Fasteners & Bolts

- Files and Specialty Tools

-

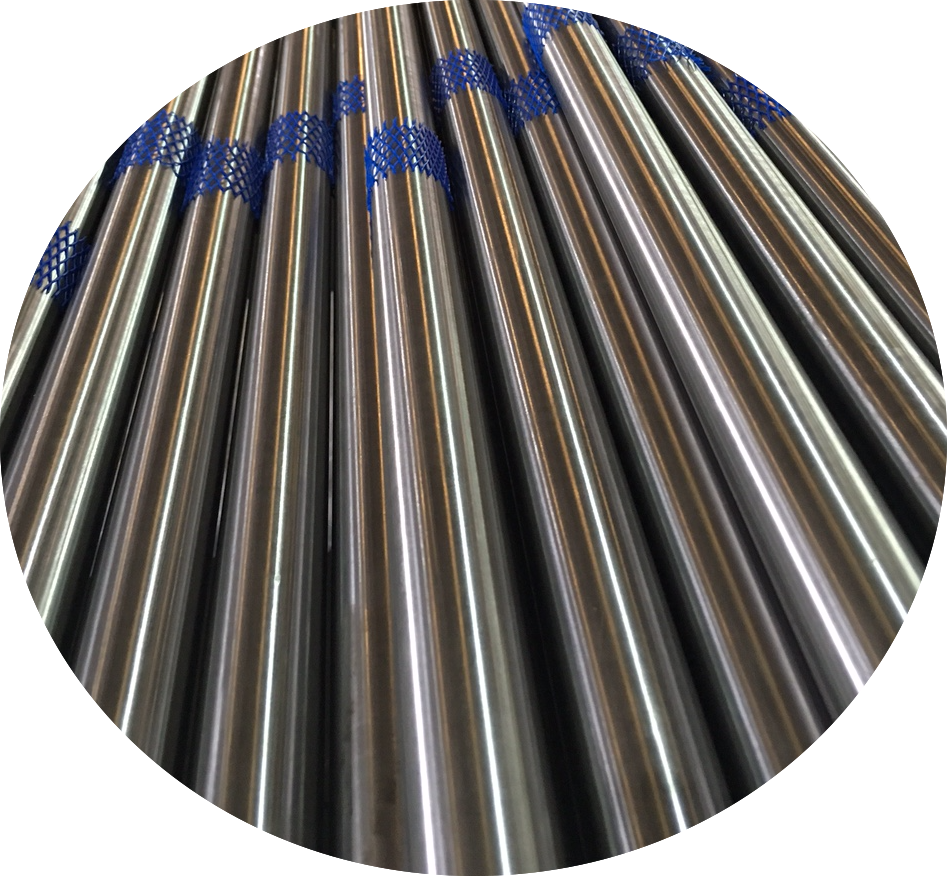

Precision Ground Shafts

Precision Ground ShaftsCarbon, Alloy and Stainless Steel Grades available in precision ground shafts in Annealed, Quench/Hardened & Tempered, Cold Drawn, Strain Hardened Condtions, or to your specific mechanical requirements.

SIZE RANGE:

Bars: 1/2" to 3" (12mm to 76mm)

Lengths: Cut lengths as per requirement, or up to 22ft

QUICK DELIVERY GRADES AND SIZES:

Grades: 416, 316/L, 4140, 1018

Sizes: 1", 1 3/16", 1 1/4", 1 7/16", 1 1/2", 1 11/16", 1 3/4", 1 15/16", 2"

SHAFT MATERIAL SPECIFICATIONSGrade / Description Specifications Tensile Str.

(Ksi) min.Yield Str.

(Ksi) min.Elongation

(%) min.Reduction of

Area (%) min.Hardness

(BHN)316

UNS S31600ASTM A-276 Condition A;

ASTM A479 Condition A;

ASME SA 479;

QQS-763;

AMS 5648; AMS 565375 30 30 40 222 max. 410

UNS S41000ASTM A479 Condition 2;

ASME SA 479110 85 15 45 223 - 269 416

UNS S41600ASTM A582;

ASME SA 582; AMS 5610100 85 15 - 23 50 207 - 269 416 T

UNS S41600ASTM A582 Condition T;

ASME SA 582; AMS 5610100 85 15 - 23 50 255 - 302 17-4

UNS S17400ASTM A564 Type 630;

Condition H1150; ASME SA 564;

AMS 5643135 105 16 50 277 - 352 4140 Q&T (B7)

UNS S414000ASTM A29

ASTM A193105 125 16 50 330 max. -

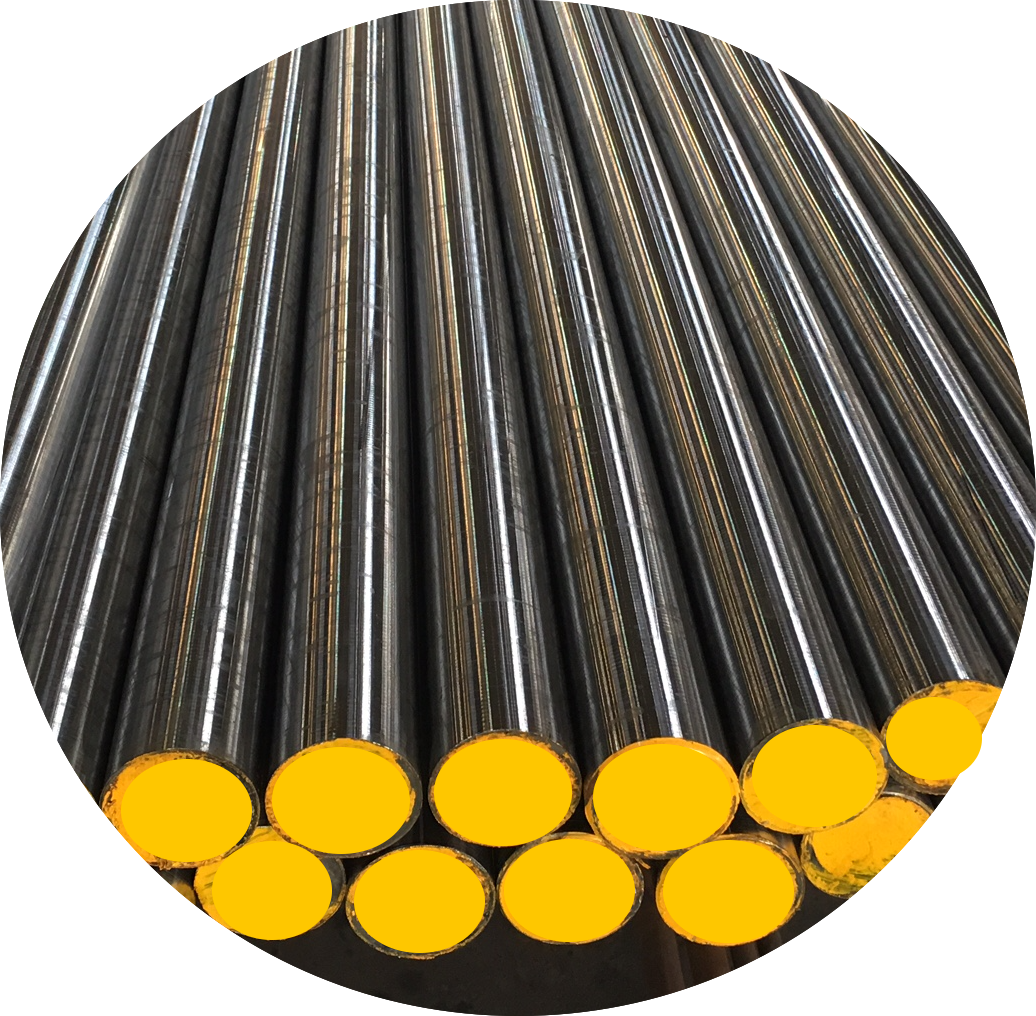

400 Series Rounds

400 Series RoundsSupplied in annealed and H&T condition, including Pump Shaft Quality. We can offer up to 4" dia. at very competitve prices. AISI 440C also available.

Ferritic stainless steels are typically used where moderate corrosion resistance is required and where toughness is not a major need. They are also used where chloride stress-corrosion cracking may be a problem because they have high resistance to this type of corrosion failure. In heavy sections, achieving sufficient toughness is difficult with the higher-alloyed ferritic grades. Typical applications include automotive trim and exhaust systems and heat-transfer equipment for the chemical and petrochemical industries.

Martensitic stainless steels are used where strength and/or hardness are of primary concern and where the environment is relatively mild from a corrosive standpoint. These alloys are typically used for bearings, molds, cutlery, medical instruments, aircraft structural parts, and turbine components. Type 420 is used increasingly for molds for plastics and for industrial components requiring hardness and corrosion resistance.

FERRETIC AND MARTENISTIC STEELSGr. %C %Mn %Si %P %S %Ni %Cr Mecha. Prop. (Hardness BHN) Comparision of International Standards MAX MAX MAX MAX MAX Annealed QT (cond.T) QT (cond.T) AISI DIN B.S. JIS 410 0.15 max 1.00 1.00 0.040 0.030 - 11.50-13.50 262 max 248-292 - 410 1.4006 410S21 SUS410 416 0.15 1.25 1.00 0.060 0.150 min - 12.00-14.00 262 max 248-292 293-352 416 1.4005 416S21 SUS416 420 0.15 min 1.00 1.00 0.040 0.030 - 12.00-14.00 262 max 248-292 - 420 1.4021 420S37 SUS420J1 430 0.12 1.00 1.00 0.040 0.030 0.75min 16.00-18.00 262 max - - 430 1.4046 430S15 SUS430 430F 0.12 1.25 1.00 0.060 0.150 min 0.75min 16.00-18.00 262 max - - 430F 1.4046 - SUS430F 431 0.20 1.00 1.00 0.040 0.030 1.25-2.50 15.00-17.00 - 248-292 - 431 1.4057 431S29 SUS431 440C 1.2 1.00 1.00 0.040 0.030 - 16.00 - 18.00 * * * 440C 1.4125 - SUS440C -

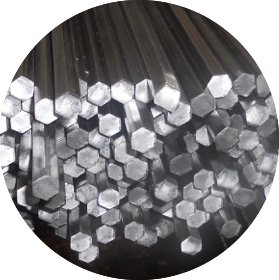

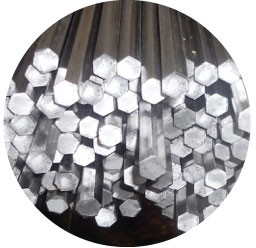

303 Hex & Square

303 Hex & Square303 is one of the most popular of all the free machining stainless steels. It offers good strength, corrosion resistance and great machinability. It will resist scaling at temperatures up to 1600 F(871 C)..

Used in an incredibly wide variety of parts both in screw and general machining industries. Applications include hardware, fasteners, valve parts, nozzles and trim.

HEXAGONAL BARS

Execution MM Inches ISO Tolerance Cold Drawn 4.00 - 76.00 3/16" – 3" h11 SQUARE BARS

Execution MM Inches ISO Tolerance Cold Drawn 4.00 - 76.00 3/16" – 3" h11